Blog

Integrating 3D Concrete Printing into South African Civil Engineering Curricula

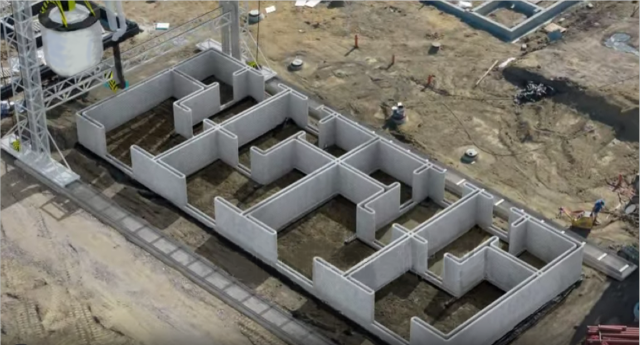

Imagine building a full RDP house in under 8 hours—costing 30–60% less in materials and labor—while slashing carbon emissions by up to 70%. That’s not sci-fi; it’s 3D concrete printing (3DCP), and South Africa’s 2.2 million housing backlog demands it now.

South Africa’s civil engineering graduates are entering a stalled industry: high labor costs, material waste, and slow builds exacerbate the housing crisis, with informal settlements swelling and SDG 11 (sustainable cities) at risk. Traditional curricula ignore this digital revolution, leaving students unprepared for automated construction that’s already piloted at some South African universities —yet adoption lags due to regulatory hurdles, prohibitive printer costs (see pricing on the Building Bot) and skill gaps.

Embed 3DCP courses in your civil engineering departments: hands-on modules on mix design, robotic extrusion, and sustainable inks. This equips students to innovate with complex geometries, zero formwork, and waste reduction—aligning with DSI’s human settlements push and global trends transforming infrastructure. Graduates become leaders in green building, boosting employability by 50% in a digitized sector.

Benefits are game-changing: Cut construction time by 50–70%, labor by 50–80%, and waste by 30–60%—directly tackling SA’s backlog while fostering innovation.

Your institution leads as a hub for SDG 4 (quality education) and 9 (innovation), attracting top talent and funding like UJ’s DSI pilot.

UJ printed SA’s first 3D house in a day; reducing emissions and enabling rapid prototyping—proven in 2023 pilots.

Partner with us: Acquire our affordable 3DCP printers (under R1M)—highly mobile, with customizable open source control which is ideal for teaching institutions —and launch your first course next semester. Schedule a more in depth presentation today.

Don’t lag in the print revolution—build tomorrow’s engineers today. Let’s 3D-print South Africa’s sustainable future, one layer at a time.